CellufinecTM MAX Butyl

CellufineTM MAX Phenyl

CellufineTM MAX Phenyl LS

CellufineTM MAX is a 2nd generation Cellufine media with high flow characteristics. JNC developed a new, highly cross-linked base resin for Cellufine MAX series. Cellufine MAX hydrophobic interaction chromatography is now available with MAX Phenyl and Butyl chemistries.

Cellulose, a natural polysaccharide, possesses unique crystalline molecular structure differing from non-crystalline polysaccharides such as agarose. Thus Cellufine has distinctive pore structure as shown in the pictograph (Fig. 1). The new Cellufine MAX series offers the largest pore size of all Cellufine chromatography media. The benefit of such pore size in Cellufine MAX HIC media provides superior strength and excellent mass transfer.

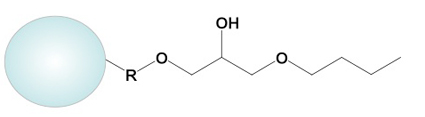

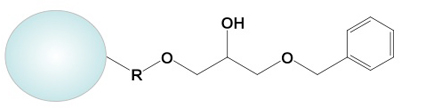

Partial structure

-

Hydrophobic Interaction

Cellufine MAX Butyl

-

Cellufine MAX Phenyl

Cellufine MAX Phenyl LS

Characteristics

| Characteristics | |||

|---|---|---|---|

| Type | Cellufine MAX Butyl | Cellufine MAX Phenyl | Cellufine MAX Phenyl LS |

| Matrix | Highly Cross-linked Cellulose | ||

| Particle size | 40~130 μm | ||

| Ligand type | Butyl | Phenyl | |

| BSA adsorption capacity (mg/ml) | 9 | 11 | 4 |

| BSA elution efficiency (%) | 70 | 40 | 90 |

| Polyclonal IgG 10% DBC (mg/ml) | 17 | 30 | 19 |

| Operating pressure | < 0.3 MPa | ||

| pH stability | pH 2 ~ 13 | ||

| Storage | 20 % Ethanol | ||

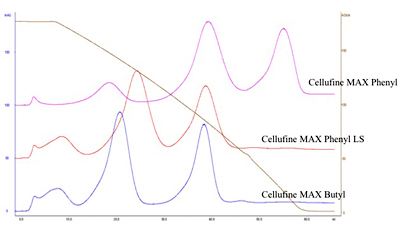

Model Protein Separation

- Column

- 6.6 mm ID x 50 mm L

- Buffer A

- 10 mM phosphate buffer (pH 7) + 1.5 M (NH4)2SO4

- Buffer B

- 10 mM phosphate (pH 7)

- Proteins

- Ribonuclease A, Lysozyme, α-Chymotripsinogen A

Adsorption Capacity of Model Proteins

- Column

- 5 mm ID x 10 cm L

- Protein concentration

- 1 mg/ml

- Buffer

- 50 mM Tris-HCl (pH 8.5)

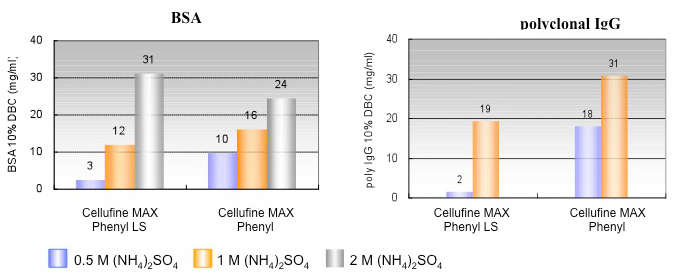

Dynamic Binding Capacity for Cellufine MAX Phenyl vs. Salt Concentration

- Column

- 5 mm I.D. x 5 cm L

- Flow velocity

- 150 cm/hr

- Protein concentration

- 1 mg/ml

- Buffer

- 20 mM Phosphate (pH7.0) + (NH4)2SO4

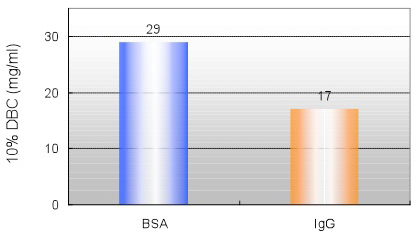

Dynamic Adsorption Capacity for Cellufine MAX Butyl

- Column

- 5 mm I.D. x 5 cm L

- Flow rate

- 0.5 ml/ min

- Protein concentration

- 1 mg/ml

- Buffer

- 10 mM Phosphate (pH 7.0) +

2 M (NH4)2SO4 / BSA

1 M (NH4)2SO4 / polyclonal IgG

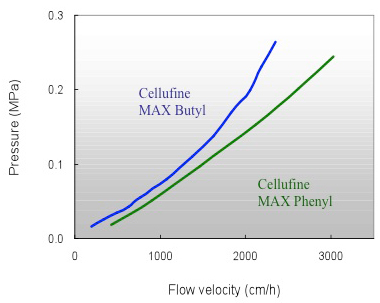

Pressure vs. Flow Properties

- Column

- 2.2cm I.D. x 20 cm L

- Temperature

- 24 ± 1 ℃

- Mobile phase

- Water

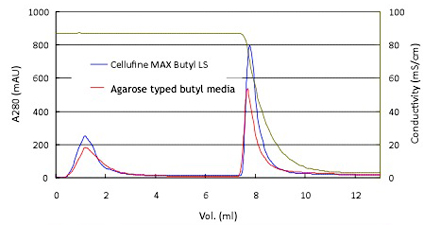

Ligand density is controllable in Cellufine MAX HIC Ex.) Purification of HBsAg by Cellufine MAX Butyl

As ligand density is controllable, Cellufine MAX HIC is optimized for customer’s purpose.

The

figure shows a chromatogram of adsorption-desorption of r Hepatitis B virus particles to

Cellufine MAX Butyl LS (optimization for HBV) and Agarose typed butyl media

| Cellufine MAX Butyl LS | Agarose typed Butyl media | |

|---|---|---|

| Load | 163 (100) | 163 (100) |

| Flowthrough | 48 (29) | 50 (31) |

| Eluted target | 78 (48) | 63 (39) |

μg(%)

Run condition

- HIC resin

- Cellufine MAX Butyl LS and Agarose typed butyl media

- System

- AKTA explorer 10S

- Column

- Φ3.0 x 50 mm (vol. 0.35 ml)

- Sample

- 150 mg of r-HBsAg (Beacle Inc.) in 0.02 M PB, 0.6M (NH4)2SO4, pH 7.0

- Equilibration and wash

- 0.02 M PB, 0.6M (NH4)2SO4, pH 7.0

- Elution 1

- 0.02 M PB, pH 7.0

- Flow rate

- 0.25 ml/min(220 cm/hr)

Chemical and Caustic Stability

- Ethanol (70%)

- NaOH (0.5M)

- Isopropyl alcohol (30%)

- Detergents

- Guanidine hydrochloride (6M)

- Autoclave (121 ºC, 20 min)

- Urea (6M)

- Cellufine MAX Butyl

- Cellufine MAX Phenyl

- Cellufine MAX Phenyl LS