Cellufine™MAX Q-hv

Cellufine™MAX Butyl HS

Streptococcus pneumoniae is one of the major pathogens causing high level morbidity and mortality worldwide, especially children and the elderly populations. Pneumococcal vaccines based on the capsular polysaccharide (CPS) on the bacteria surface, which is one of the most important virulence factors, have been used to prevent these infectious diseases.

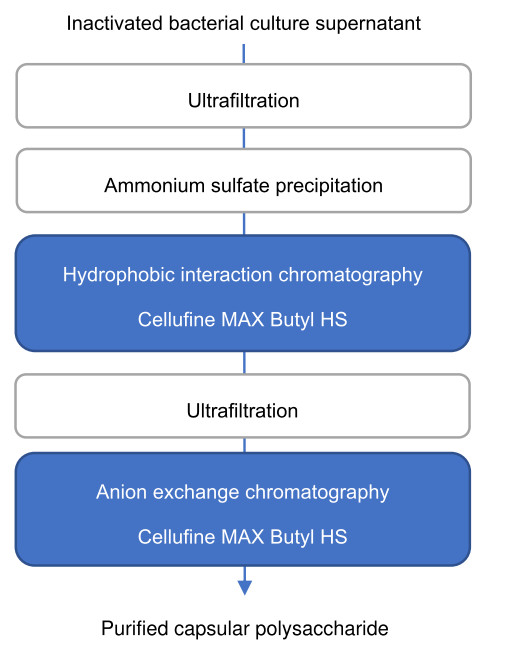

By using two-step chromatography purification to purify the capsular polysaccharide, it is possible to purify the vaccine to a high degree of purity.

This process includes hydrophobic interaction chromatography (HIC) and anion exchange chromatography (AEX). We introduce two optimized resins, Cellufine MAX Butyl HS (HIC) and Cellufine MAX Q-hv (AEX), for this process.

Features of Cellufine™ MAX Q-hv

Cellufine MAX Q-hv is a strong anion exchanger. There are several strong anion exchangers in Cellufine's product line, and we will introduce a comparison between them. Cellufine MAX Q-hv has optimized ligand concentration for optimal purification of capsular polysaccharide.

| Comparison of Cellufine™ MAX Q series | |||

|---|---|---|---|

| Grade | Cellufine™ MAX Q-r | Cellufine™ MAX Q-h | Cellufine™ MAX Q-hv |

| Base resin | Highly cross-linked cellulose with dextran scaffold | ||

| Particle size | ca. 40~130 μm | ||

| Lignad | Strong anion / -N+(CH3)3 | ||

| Ion exchange capacity (meq/ml) | 0.10~0.20 | 0.13~0.22 | 0.04~0.07 |

| DBC BSA (mg/ml) | 110 | 180 | 120 |

| Flow velocity | 600 cm/h(0.3 MPa), I.D.30 cm-L20 cm, pure water at 24 ºC | ||

| pH stability | pH 2 - 12 | ||

| Chemical stability | Stable all commonly used aqueous buffers | ||

| CIP | 1 M NaOH | 0.5 M NaOH | |

| Storage | 20 % ethanol | ||

Features of Cellufine™ MAX Butyl HS

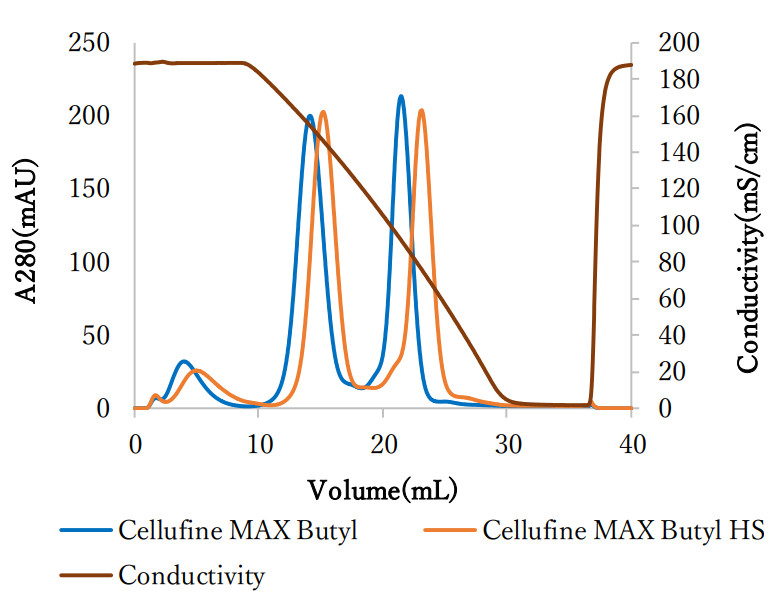

Cellufine™ MAX Butyl HS is a hydrophobic interaction chromatography resin with a butyl group. There are several HIC resin in Cellufine's product line, and we will introduce a comparison between them. Cellufine™ MAX Butyl HS has optimized ligand concentration for optimal purification of capsular polysaccharide.

| Comparison of Cellufine™ MAX Butyl series | ||

|---|---|---|

| Grade | Cellufine™ MAX Butyl | Cellufine™ MAX Butyl HS |

| Base resin | Highly cross-linked cellulose | |

| Particle size | ca. 40~130 μm | |

| Ligand | Low conc. butyl group | High conc. butyl group |

| BSA adsorption capacity (mg/ml) | 9 | 13 |

| BSA elution efficiency (%) | 70 | 36 |

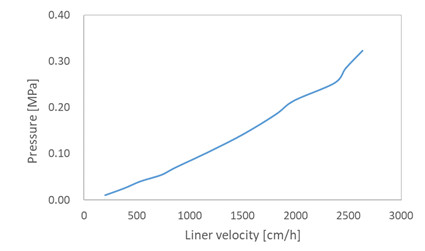

| Operating pressure | <0.3 MPa | |

| pH stability | pH 2 - 13 | |

| Chemical stability | Stable in commonly used buffers | |

| CIP | 1 M NaOH | |

| Storage | 20 % Ethanol | |

Protein Separation Performance for Cellufine MAX Butyl HS

- Column

- 6.6 mm ID x 30 mmL (1.0 ml)

- Buffer A

- 10 mM Na phosphate, 1.5 M ammonium sulfate, pH 7.0

- Buffer B

- 10 mM Na phosphate, pH 7.0

- Protein

- Ribonuclease A, Cytochrome C, Lysozyme

Flow property of Cellufine™ MAX Butyl HS

- Column

- 2.2cm I.D. x 20 cm L

- Temperature

- 24 ± 1 ℃

- Mobile phase

- Pure water

Purification of capsular polysaccharide of Streptococcus pneumoniae serotype 19F

Streptococcus pneumoniae is one of the major pathogens causing high level morbidity and mortality worldwide, especially children and the elderly populations. Pneumococcal vaccines based on the capsular polysaccharide (CPS) on the bacteria surface, which is one of the most important virulence factors, have been used to prevent these infectious diseases. Traditional ethanol precipitations are general processes for purifying CPSs, which are suitable for most serotypes. However, they are complex and time consuming. As a result, pneumococcal vaccines are quite expensive. To overcome these disadvantages, a lot of improved processes are proposed. Some of these processes include chromatography processes. Here we would like to propose simplified two step chromatography purification process of CPS without ethanol precipitations. This process includes hydrophobic interaction chromatography (HIC) and anion exchange chromatography (AEX). We introduce two optimized resins, Cellufine™ MAX Butyl HS (HIC) and Cellufine™ MAX Q-hv (AEX), for this process.

| PS Recovery % |

PS Purity % | Protein μg/mL |

Nucleic acid μg/mL |

Protein / PS % |

Nucleic acid / PS % |

|

|---|---|---|---|---|---|---|

| Load sample | - | 46 | 73 | 772 | 10 | 106 |

| MAX Butyl HS after purification |

89 | 54 | M.D. | 436 | 0 | 84 |

| MAX Q-hv after purification |

98 | 99 | N.D. | 4 | 0 | 1 |

Chemicai stability

Stable in the following solvents and autoclaves.

- Ethanol (70%)

- Sodium hydroxide (0.5M)

- Isopropanol (30%)

- Surfactant

- Guanidine hydrochloride (6M)

- Autoclave (121 ºC, 20 min)

- Urea (6M)

- Cellufine™ MAX Butyl HS

- Cellufine™ MAX Q-hv