Cellufine Phenyl EX

Cellufine Phenyl EX is a chromatography resin that can efficiently remove aggregates of antibody drugs using our unique ligand modification technology. The antibody aggregates are captured to the column, but most of the antibody monomers are recovered as they are in the flow-through fraction. Cellufine Phenyl EX can be used for flow-through purification that selectively adsorbs such as aggregates.

| Characteristics | |||

|---|---|---|---|

| Grade | Cellufine Phneyl EX | Cellufine MAX Phenyl | Cellufine MAX Phenyl LS |

| Base | Cross-linked cellulose | Highly cross-linked cellulose | Highly cross-linked cellulose |

| Particle diameter | ca. 40~130 μm | ||

| Ligand | Phenyl group | ||

| BSA adsorption capacity [mg/ml] | 13 | 11 | 4 |

| BSA recovery [%] | 30 | 40 | 90 |

| Operating pressure | < 0.2 MPa | < 0.3 MPa | < 0.3 MPa |

| pH stability | pH 2 - 13 | ||

| Supplied | Suspension in 20 % EtOH | ||

Partial structure

-

Cellufine Phenyl EX

Ligand

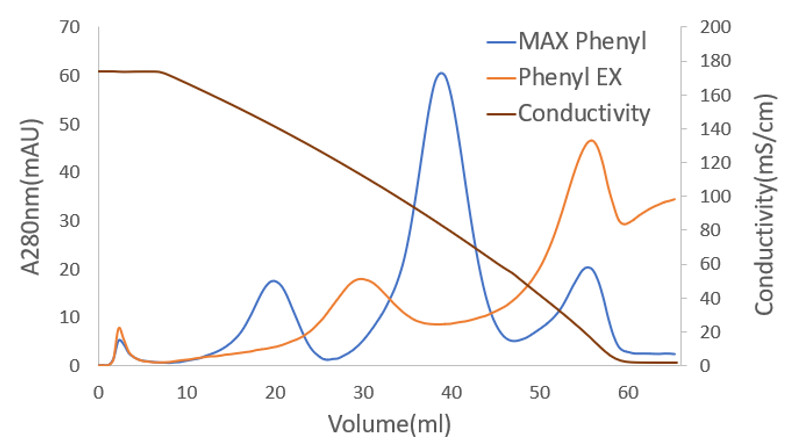

Model Protein Separation

The optimum amount of ligand for HIC resins vary depending on the application. Below figure shows model protein separation with Cellufine Phenyl EX and Cellufine MAX Phenyl. Protein separation studies show that relative binding strength are Phenyl EX > MAX Phenyl. The strength of hydrophobicity is also Cellfine Phenyl EX > Cellfine MAX Phenyl.

- Column

- 6.6 mm ID x 50 mm L

- Buffer A

- 10 mM Phosphate buffer, pH 7

- Buffer B

- 10 mM Phosphate buffer, pH 7 + 1.5 M Ammonium sulphate

- Protein

- Ribonuclease A, α-chymotrypsinogen A, Lysozyme

Purification of antibody aggregates

Cellufine Phenyl EX is the best chromatography resin for removing aggregates from monoclonal antibodies in flow-through mode. Antibody aggregates were removed using the monoclonal antibody purified with a protein A column. Cellufine Phenyl EX can be worked with low electrical conductivity and has high agglomerate removal properties. In this study, the conductivity of the sample was adjusted to 6 mS / cm. For this reason, it is possible to suppress corrosion of pipes and buffer precipitation due to high salt concentration, which is used with ordinary HIC resins.

- Column

- 1 mL mini column

- Flow

- Residence time 4 min (75cm/h)

- Sample

- mAb after protein A column 6.6 mg/mL, pH6, 6 mS/cm

- Load antibody

- 93 mg_mab/mL_CV

- Equilibration and wash

- 20 mM AcOH-Tris + NaCl, pH6, 6 mS/cm

As shown in Table, the monoclonal antibody aggregate was present at 3.6% before column loading, but it was reduced to 0.4% by passing Cellufine Phenyl EX.

| Resin | Aggregate (Before load)[%] | Aggregate (After load)[%] | Recovery [%] |

|---|---|---|---|

| Cellufine Phenyl EX | 3.6 | 0.4 | 87 |

| Cellufine MAX Phenyl | 3.6 | 1.3 | 99 |

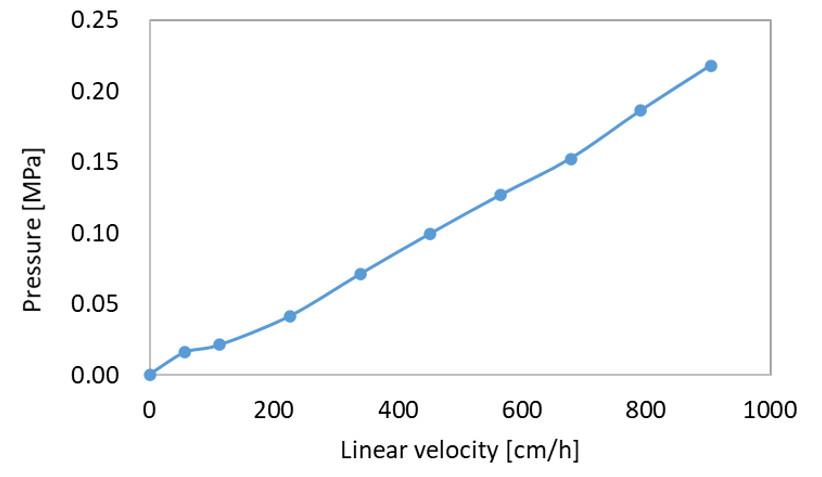

Flow Property

Cellufine Phenyl EX enable high-flow operation, which is essential to efficient purification of biopharmaceuticals. Cellufine Phenyl EX is operable at practical flow velocities and pressures.

- Column

- 2.6cm I.D. x 19.3 cm L

- Temperature

- 23 - 25 °C

- Mobile phase

- Pure water Resin was packed with a compression factor 1.35. System pressure was excluded from the data.

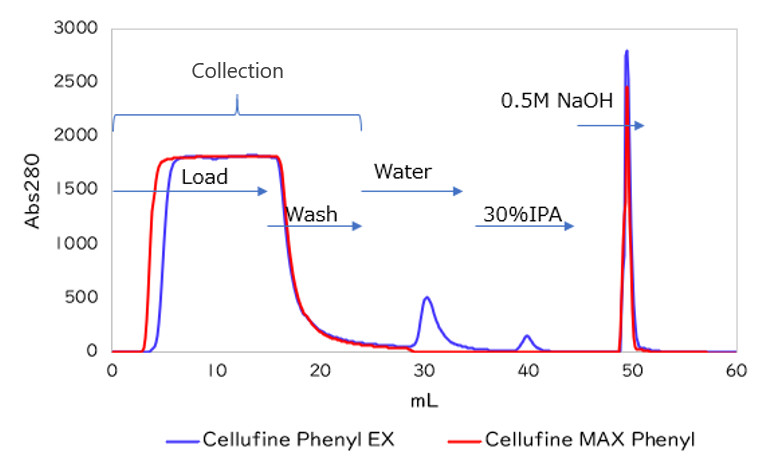

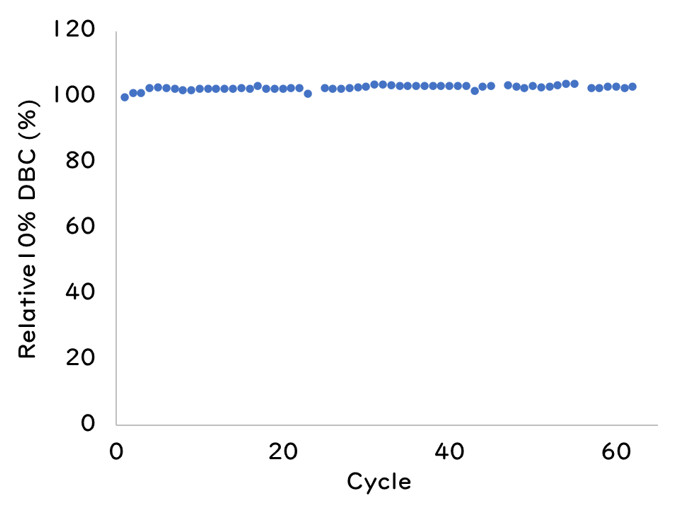

Repeat use

Cellufine Phenyl EX can be used repeatedly. For cleaning-in-place, use a cleaning solution containing 0.5 M sodium hydroxide and 30% isopropanol. By performing cleaning-in-place with an appropriate cleaning solution, the adsorption performance did not change even after repeated use 60 times.

- Column

- 1 mL Mini-Column

- Sample

- Human gamma globulin 2 mg/mL, in equilibration buffer

- Equilibration衡化

- 20 mM Phosphate buffer, 0.5 M Ammonium Sulphate, pH7.0

- Elution

- 20 mM Phosphate buffer, pH7.0

- CIP

- 0.5M NaOH+30% IPA(10 CV、Exposure time: 20 min)

Chemical Stability

Usable chemicals

- Ethanol (70%)

- Sodium hydroxide (0.5M)

- Isopropyl alcohol (30%)

- Detergents

- Guanidine hydrochloride (6M)

- Autoclave (121 ºC, 20 min)

- Urea (6M)

- Cellufine Phenyl EX

- Cellufine MAX Phenyl

- Cellufine MAX Phenyl LS